- Home

- Products

-

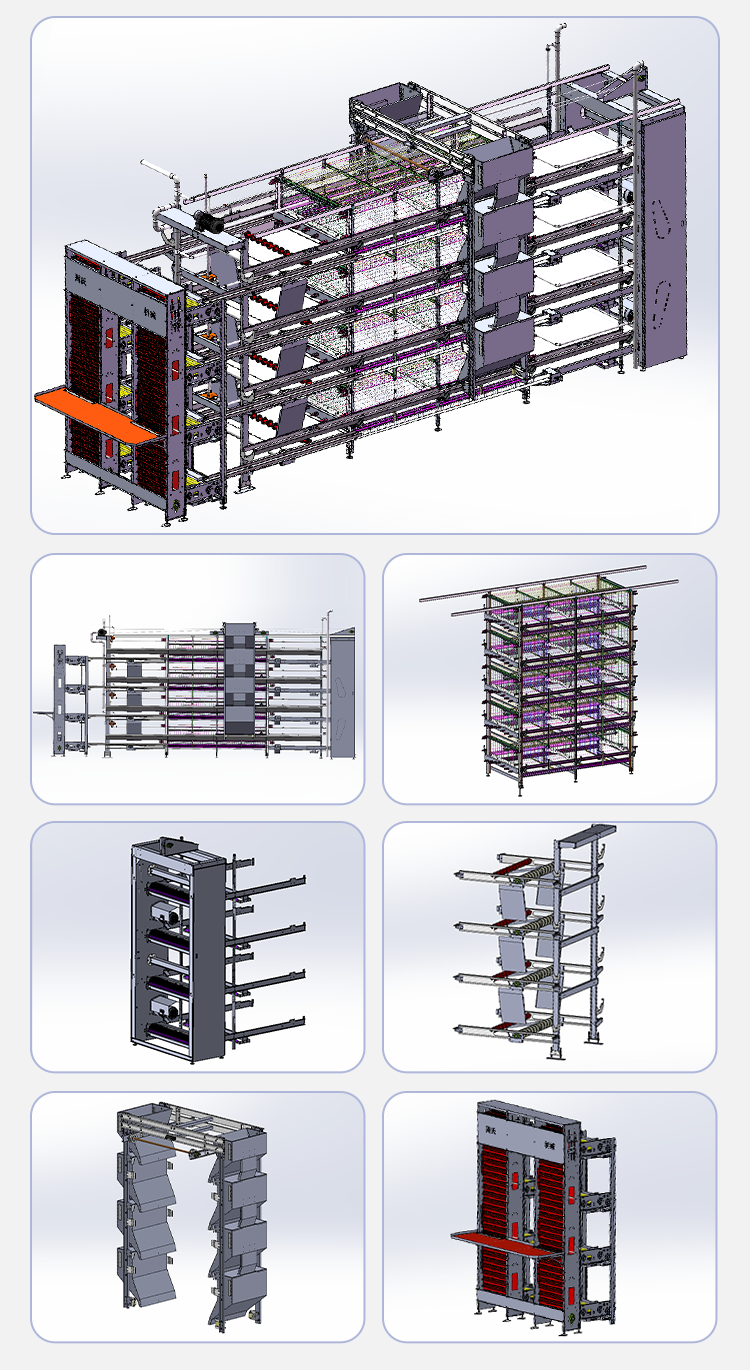

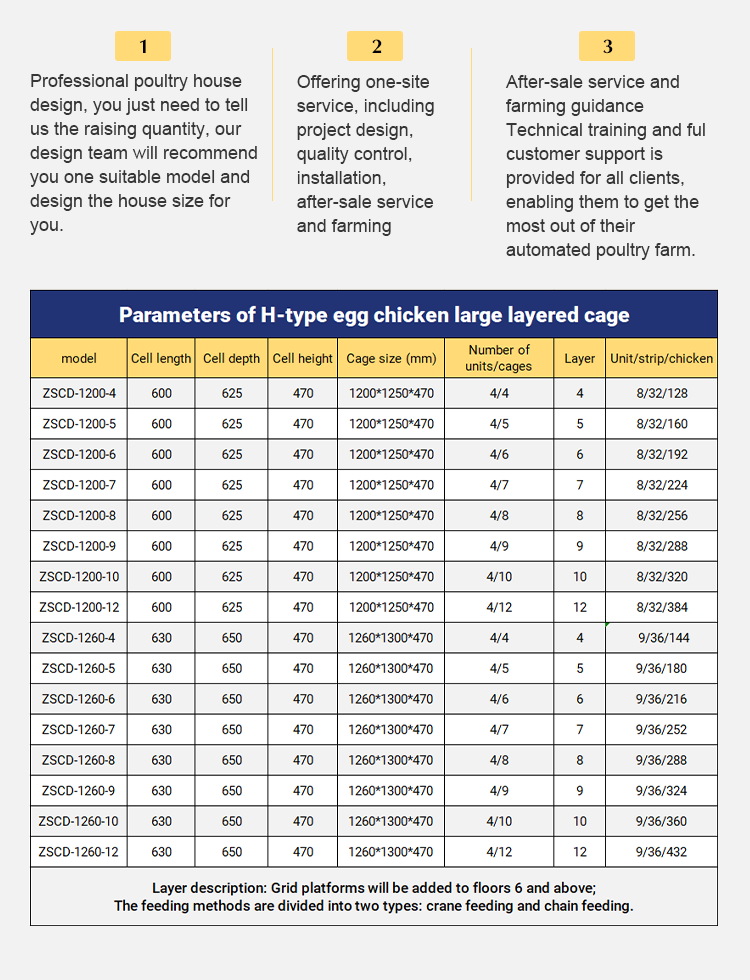

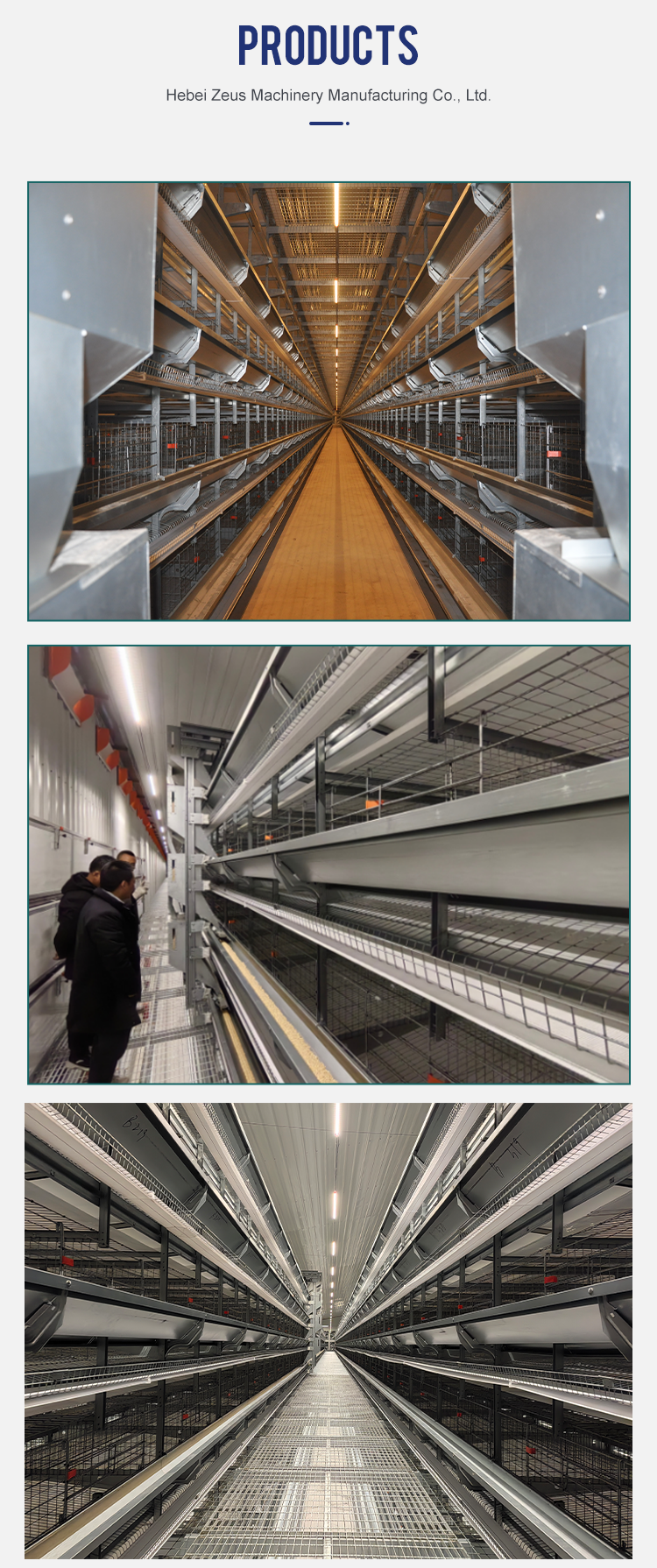

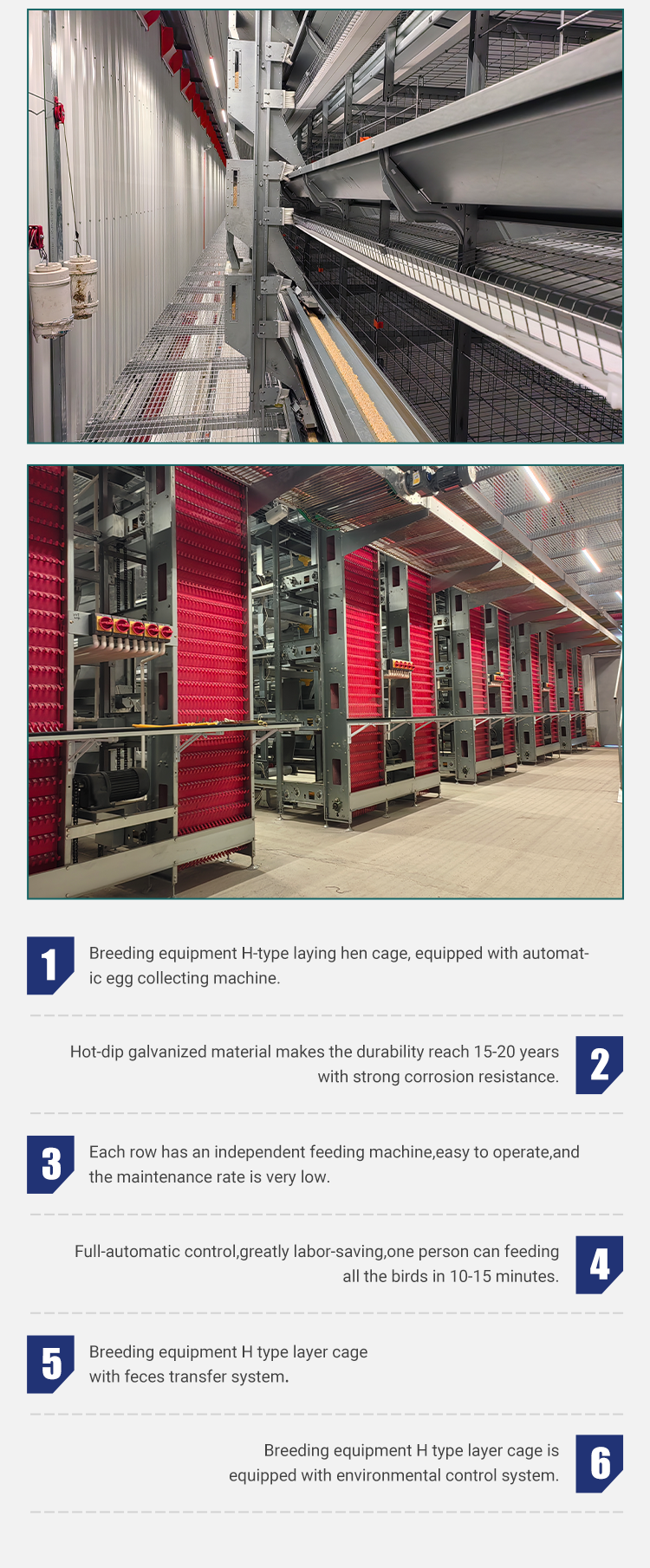

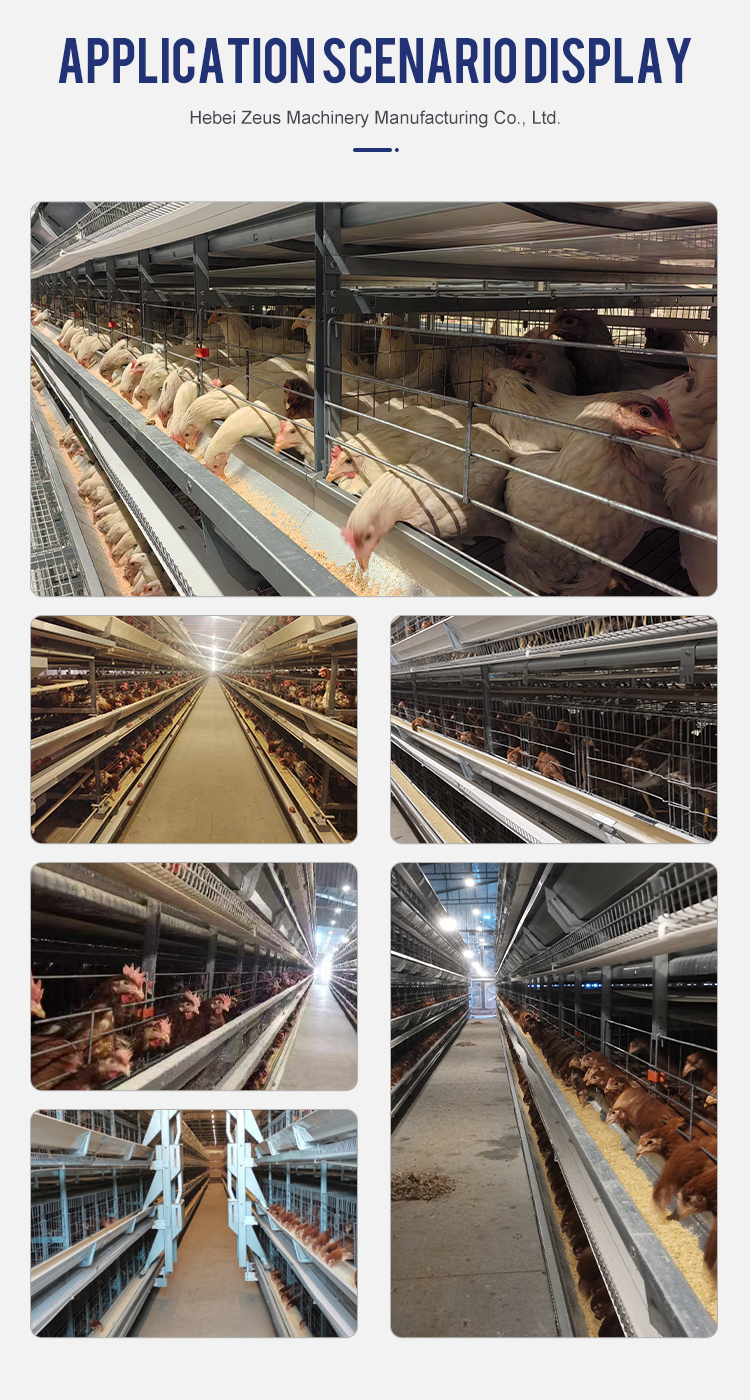

- Layer Cage Equipment

- Broiler Cage Equipment

- Brooding Cage Equipment

- Stacked Cage Equipment

- Breeder Cage Equipment

- Duck Breeding Cages

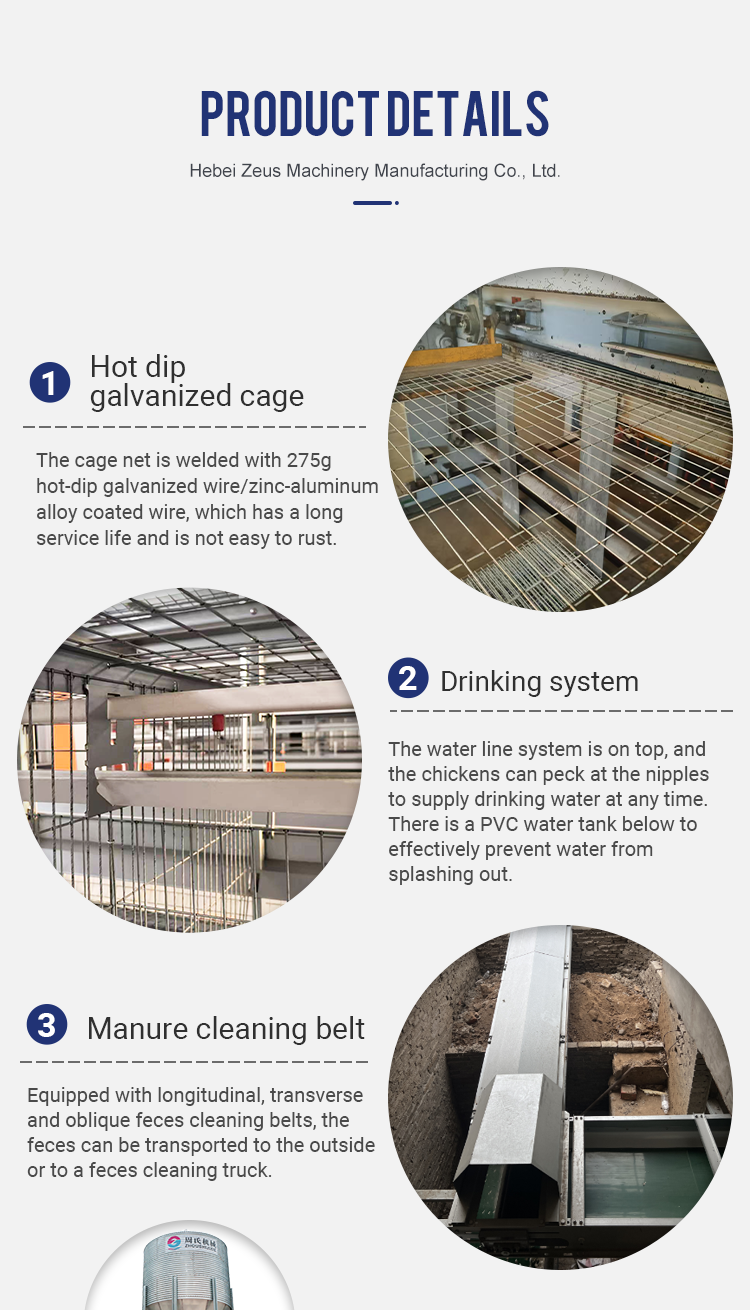

- Automatic Drinking System

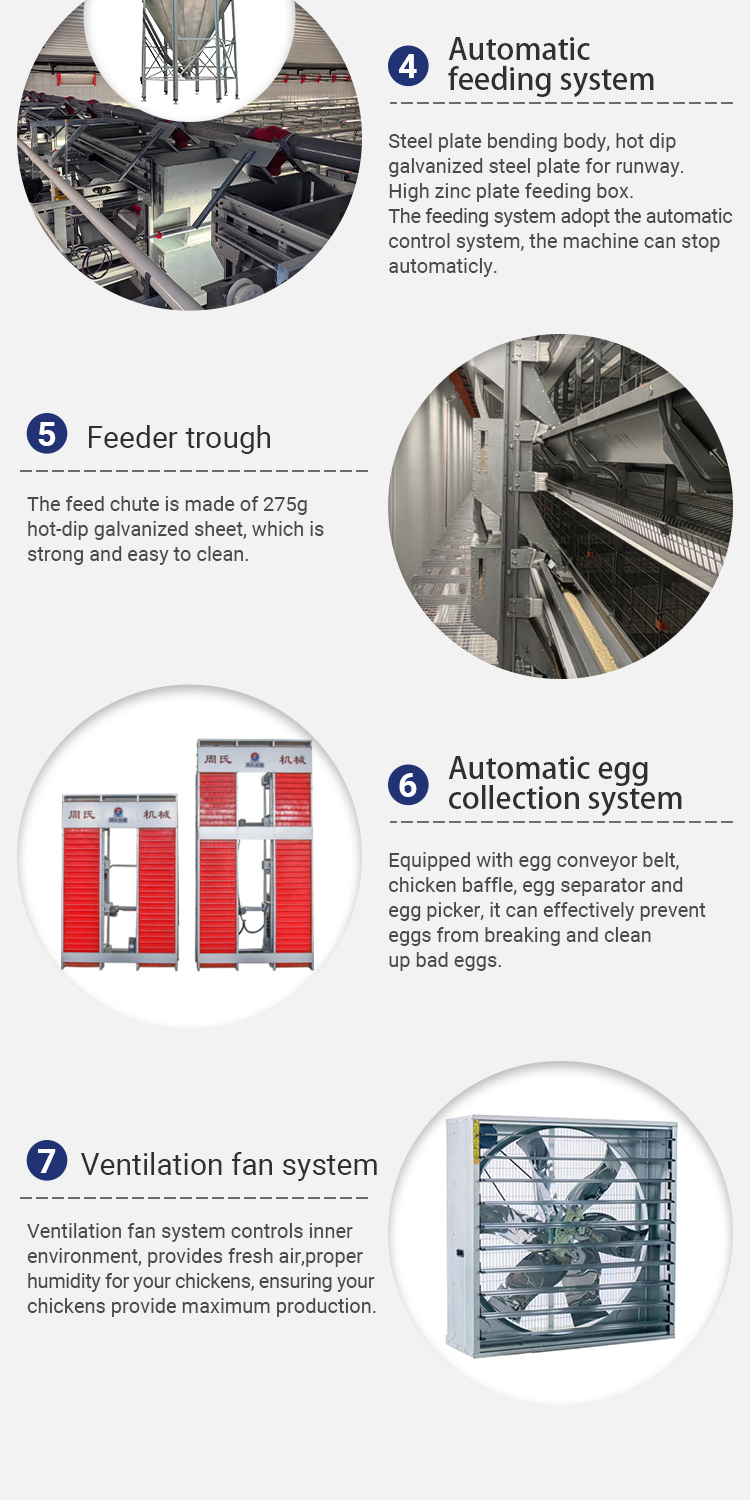

- Poultry Feeding System

- Automatic Egg Collecting System

- Cooling And Ventilating System

- Cooling Water Curtains

- Poultry Fans

- Breeders Naturally Mate With Cages

- Feed Tower

- Electric Control System

- Livestock Environmental Controller

- Livestock Manure Fermentation Equipment

-

-

-

-

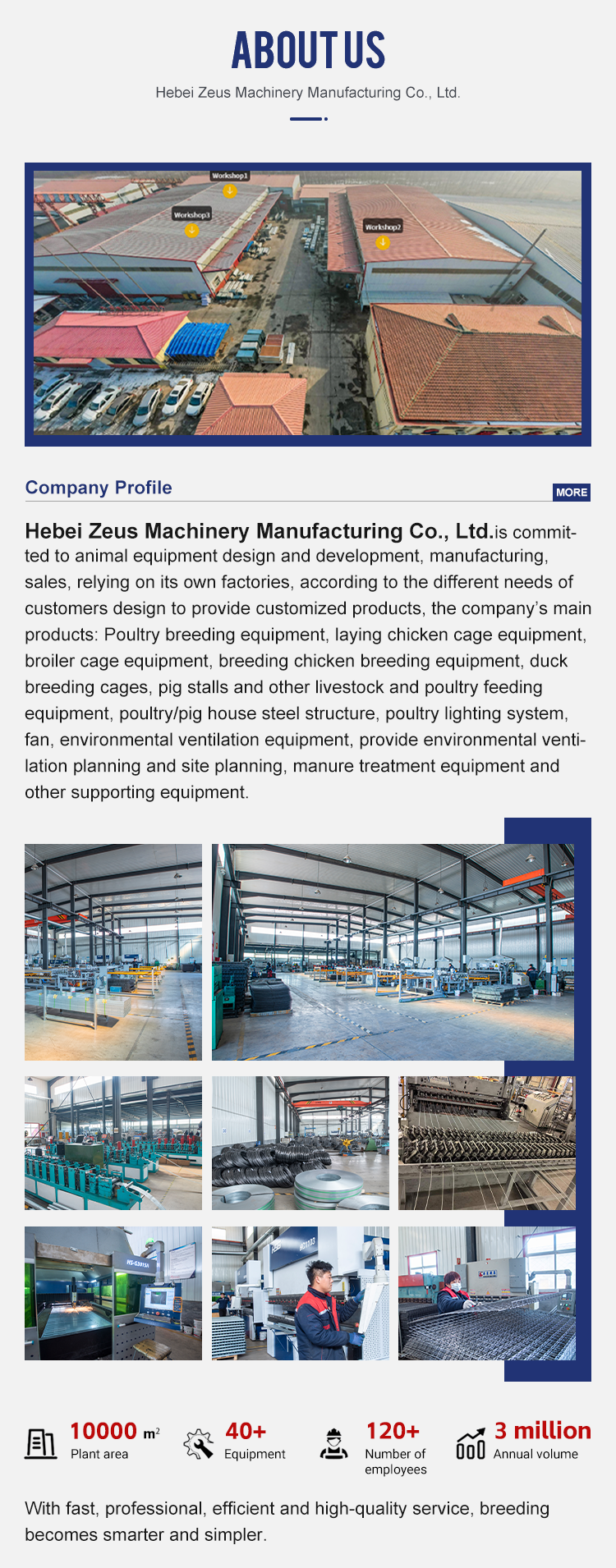

- About Us

- Projects

- Service

- Blogs

- Contact Us

English

+86-15030729981

www.zeushebei.com

www.zeushebei.com

Economic Development Zone, Cang City, Hebei Province, China.